NEED HELP?

WE ARE HERE TO HELP YOU

As a pioneer in the field of ductless car park systems with jet fans in the early 90s, NOVENCO Building & Industry set new standards for the ventilation of closed parking facilities.

Cars have become a natural part of everyday life. Despite widespread public transport systems, nowadays most people own a car. Parking facilities are therefore in great demand, particularly in cities and large towns. Conventional, open car parks take up far too much space, while people tend to prefer parks and open spaces in their cities. In other situations, such as climate conditions or a desire to prevent parked cars from being vandalized necessitate closed parking facilities. Therefore, more and more car parks are being built; both above and below ground. However, car exhaust contains several hazardous gases, carbon monoxide (CO) and benzene amongst others, and for health reasons these must be extracted from car parks.

For many years, NOVENCO has supplied fans and ventilation systems for road tunnels, and their design and further development have often taken place in close cooperation with the authorities. Since 1994, NOVENCO has put this experience to use in car park ventilation systems.

Ventilation is the transport of air. To transport air a mass must be moved. At 20°C, the density of air is approx. 1.2 kg/m³. Ventilating 10 m³ air therefore involves moving a mass of 12 kg.

Ventilation is the transport of air. To transport air a mass must be moved. At 20°C, the density of air is approx. 1.2 kg/m³. Ventilating 10 m³ air therefore involves moving a mass of 12 kg.

Air can be moved in three ways. The best known method is to transport it through ducting by means of a fan that either sucks or pushes the air through the duct. It is also well known that air moves vertically in response to thermal differentials (the so-called chimney or stack effect). The third method is known as jet ventilation and utilizes the fact that a moving body changes velocity when it is subjected to a "pushing force". In physics, this phenomenon is known as thrust.

On the basis of continuous testing, the use of thrust or jet ventilation has been optimized and integrated into car park safety systems by NOVENCO.

This article provides information on the possibilities provided by jet fans for car park ventilation.

Regarding car park ventilation systems, there are two types of car parks: open and enclosed car parks. Even car parks which are situated above ground can be an enclosed car park if there is insufficient natural ventilation.

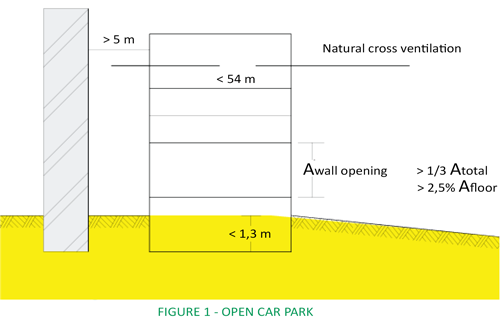

Open car parks include uncovered car parks and those that are sufficiently open to ensure the necessary ventilation. Several requirements must be met before a car park is classified as being open. Each country has its own regulations, which may be more or less stringent. Generally, requirements are more specific in countries with a longer tradition of building car parking facilities and thus more experience in their design.

As an example, all of the following requirements must be met for open car parks in The Netherlands (see figure 1):

Note: these rules differ per country!

If only one of the requirements is not met, the parking facility is classified as being an enclosed car park and therefore mechanical ventilation must be provided.

Enclosed car parks are characterized by:

Presently, four different ventilation methods are used in car parking facilities.

Natural ventilation by means of wind and thermal conditions is used in open car parks.

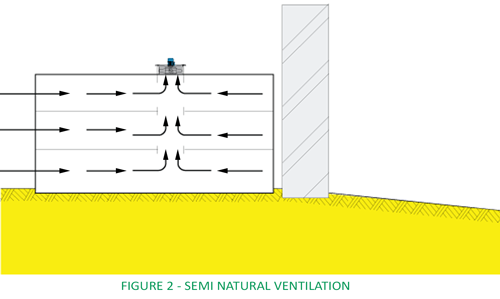

In this case the supply air will enter the car park naturally and the air will be exhausted mechanically. The opposite is also possible. The air will be supplied mechanically and the exhaust air will leave the car park by overpressure. With this method, ducts are generally not necessary.

Simple conventional ventilation is used in closed car parks. Such systems also consist of fresh-air fans and exhaust fans, but no ducts are used.

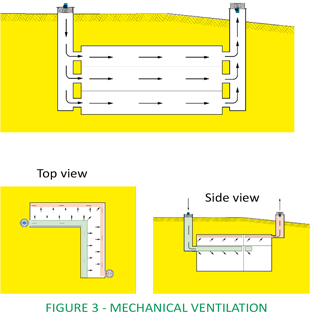

Conventional ventilation is used in closed car parks. It consists of both fresh-air fans and exhaust fans in combination with ducts for transporting air.

In practice, there are several problems with conventional car park ventilation systems.

For example:

NOVENCO jet fan ventilation systems can be adapted to cover the needs for CO ventilation and, in special circumstances, smoke control in case of fire.

In conventional ventilation systems, all air is drawn through fans and ducting. This applies to both the fresh air supplied and the discharged spent air. To prevent pressure drop, air velocity is kept as low as possible. However, this means that ducts must be relatively wide, thus requiring considerable space.

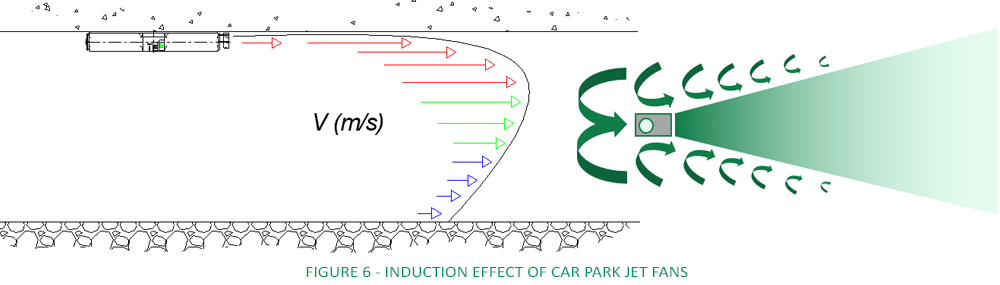

The function of jet fans is based on the impulse principle. From a small surface area (fan outlet) air is discharged at a relatively high velocity. When this air collides with the air in front of the fan, it thrusts the air forwards while at the same time drawing the surrounding air along with it (induction effect).

Therefore the surrounding air will be moved in the direction of the airflow. As a result of this induction or entrainment, the quantity of air in motion will always be considerably larger than the quantity of air passing through the fan itself.

This driving force is called the thrust or impulse force of the jet fans and is expressed in Newton [N]. The thrust is the product of the mass flow rate and the change in velocity. Thrust is the unit of measurement for jet fans, in contrast to conventional fans where output is measured in volume flow [m³/s] and pressure [Pa].

In theory, assuming that the surrounding air has zero initial velocity, the thrust generated by a jet fan is equal to the product of the volumetric air flow rate, density and the outlet velocity of the jet fan.

In theory, assuming that the surrounding air has zero initial velocity, the thrust generated by a jet fan is equal to the product of the volumetric air flow rate, density and the outlet velocity of the jet fan.

The influence of the jet fans on the surrounding air is only local. The effective working area of the jet fans depends on the type and function of the ventilation system.

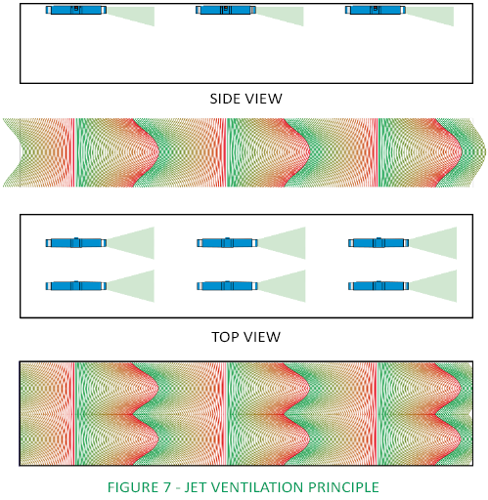

Jet fans are placed at strategic positions to ensure air movement and mixing throughout the car park. The combination of this thrust ventilation principle with mechanical exhaust and (natural and/or mechanical) fresh air supply results in an optimal ventilation system for enclosed car parks.

In car parking facilities, jet fans can be used to replace ducts for the extraction of both CO and eventually (explosive) liquid petrol gas fumes.

The presence of CO in a car park indicates that other hazardous fumes (e.g. benzene) are also present. As a result of this, the German authorities have reduced the limits for CO in car parking facilities from 100 ppm to 50-60 ppm, depending on the federal state in question.

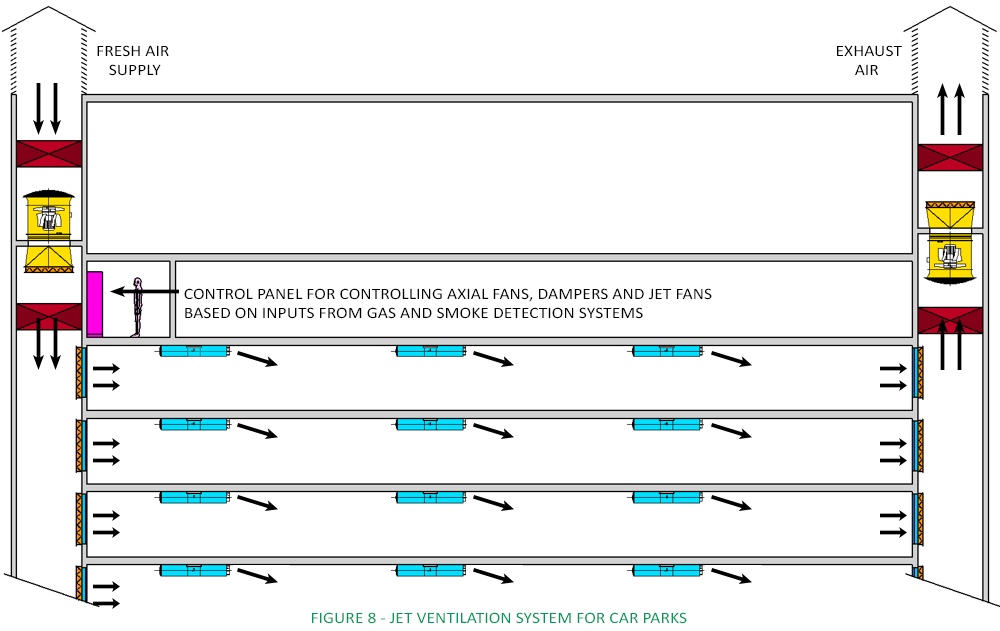

Figure 8 illustrates the possible design of a closed ventilation system consisting of jet fans and supply- and exhaust fans installed in a shaft.

The extraction unit typically consists of a grille, two exhaust fans and, if necessary, sound attenuation.

When, for example, the set limit for CO is exceeded, a signal is sent from the gas detection system to the main control panel. In the PLC (Programmable Logic Control) the associated ventilation scenario is started, which controls the correct setting of (shaft) dampers, starting the exhaust fans, followed by the supply fans and jet fans.

A ventilation system with jet fans offers numerous advantages over conventional ducted ventilation systems for car parks:

In open car parks where no ventilation system is required, natural ventilation can be supported by jet fans, thus preventing the occurrence of "dead" areas.

The same applies to parking facilities that only just fail to meet the requirements on open car parks. Here too, requirements for natural ventilation can often be met using jet fans alone.

In such cases it is often best to use 100% reversible NOVENCO car park jet fans. These fans are capable of providing the same thrust in either direction so that the direction of flow can be changed to suit wind conditions.

In Europe, almost every country has their own standards and guidelines for smoke ventilation systems in car parks. In the European Union, there is currently a draft European Standard on the design of Smoke Control Systems.

Taking the British Standard BS 7346 part 7 (2006) as a starting point, car park ventilation systems can be designed for one or more of three objectives in the event of a fire:

With regard to objective 3 it must be noted that the ceiling height for an average car park is only 2.5 – 3,0 m and therefore the height of an eventual smoke free layer is only very limited.

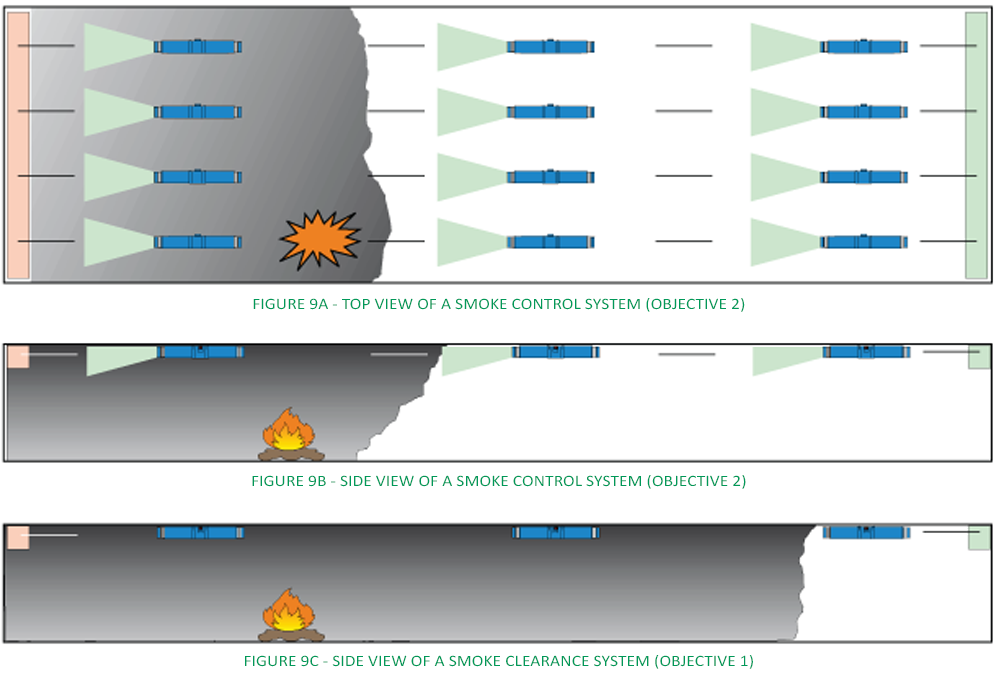

Depending on the design objective, the car park smoke ventilation system has to be designed as:

Smoke clearance systems are intended to provide ventilation to allow speedier clearance of the smoke once the fire has been extinguished. The ventilation system might also help reduce smoke density and temperature during the course of a fire.

Smoke clearance systems are not engineered solutions. This means that the smoke extract rate is provided in standards, guidelines or the building regulations. In most European countries a minimum smoke ventilation rate per fire compartment of 10 air changes per hour is required:

Qv=ACH x Vc (1)

Vc=Ac x hc (2)

Where:

Vc : volume car park / fire compartment [m³]

Ac : floor area [m²]

hc : height [m]

Qv : required smoke ventilation extract [m³/h]

ACH : air changes per hour [h-1]

These ventilation systems are designed for objective 1 of the BS 7346 part 7 and are therefore not specifically intended to maintain any area of a car park clear of smoke, to limit smoke density or temperature to within any limits.

To avoid smoke circulation and descent of the smoke layer during evacuation (objective 3), it might be preferable to either delay operation of the jet fans after automatic actuation or to provide only manual actuation from a fire service override switch.

Smoke control systems are provided specifically in order to assist fire-fighters to carry out fire-fighting operations.

Smoke control systems are provided specifically in order to assist fire-fighters to carry out fire-fighting operations.

Due to the low height in car parks vertical smoke control with a smoke-free layer is not possible. Therefore, in a car park smoke control is horizontal rather than vertical.

The system is designed to operate automatically in case of a fire detection and ensures clear, smoke-free access by fire-fighters to a point close to the seat of the fire.

Primarily, such car park smoke ventilation systems will assist fire-fighting by:

The basis of the design of a smoke control system is to prevent the smoke from back layering against the ventilation airflow by maintaining a critical air velocity.

This minimum critical velocity is dependent on a number of factors, due to which smoke control systems are always fire engineered solutions:

In large or complex car parks where jet fan ventilation is employed, there might be multiple extraction points. Smoke control systems can be designed to be fully reversible to move the smoke in one of several directions, depending on the location of the fire.

Again it is important to ensure that there are suitably located fire-fighting access points to allow the bridgehead to be created for each design fire scenario considered.

To protect the means of escape from the car park, it is advisable that upon fire detection only the main extractors and supply are put into operation. This will not disrupt the stratification despite a portion of the smoke gases being extracted quickly.

Therefore, jet fans should always be switched off during this evacuation period to avoid smoke circulation and cooling and thus the descent of the smoke layer into the occupied space. Once the jet fans have been switched on, the smoke will quickly spread to the downstream section.

Although the jet fans change the velocity distribution, they are only of limited (local) influence on the main airflow through the car park. This main average airflow is to a significant degree determined by the smoke extract rate of the main extract fans in combination with the make-up air intakes.

Through induction and mixing, the jet fan ventilation provides a considerable reduction in smoke temperatures. By reducing the smoke temperatures, the level of smoke back layering against the ventilation airflow can be reduced, providing the fire brigade with improved conditions for firefighting.

The increased airflow with smoke control will not increase the fire size since it is limited by the fuel, which is the material from the burning car.

Inside the car park there is enough oxygen available to feed the fire.

In 1998 NOVENCO has proven the method of smoke control system with full-scale fire tests in a car park in Amsterdam. During these fire tests in total 18 passenger cars were burned by an independent body (TNO – Organization for Applied Scientific Research) commissioned by the fire brigades and Dutch ministries.

Conclusions of the tests were:

It must be noted that although smoke control systems offer great benefits for the fire brigade, the design may have an impact on initial costs of the installation. The reason is that for smoke control systems higher exhaust rates are necessary, as a result of which amongst others the size of the structural shafts will increase.

The extract rate for a smoke clearance system is relative to the size of the car park whereas a smoke control system is designed to extract smoke for a given fire. As a starting point the fire size from the BS 7346-7 can be adopted:

A fire engineered approach, to the design of a smoke control system, will require the design to be based on an agreed fire load. This approach can also be used as a compensating feature for relaxations to the normal requirements of the national or local building regulations, such as for example the requirement for a sprinkler system in the car park.

A fire engineered approach may suggest that the sprinkler system is replaced by a smoke control system, but that is not the case. Whereas a sprinkler system is aimed at property protection by preventing the fire from spreading, and limiting the fire size and limiting the heat release rates, smoke control systems are aimed at providing smoke-free access for fire fighters to a point close to the seat of the fire. It is this compensating feature in relation to the ‘normal’ regulations that provide the relaxation of other requirements.

There is an important distinction to be made for sprinkler systems in car parks. Firstly, automatic fire suppression sprinkler systems are very effective in temperature control and prevention of fire spreading to other vehicles. If sprinklers are activated in the early stages of a fire, the fire size can be kept under control, and the heat release rate limited.

Due to the cooling effect of the water, mainly due to the latent heat of evaporation, temperatures are kept to acceptable levels and the fire size is controlled. Fire tests on cars in buildings with sprinklers have shown that the spread of fire between cars does not occur with an activated sprinkler.

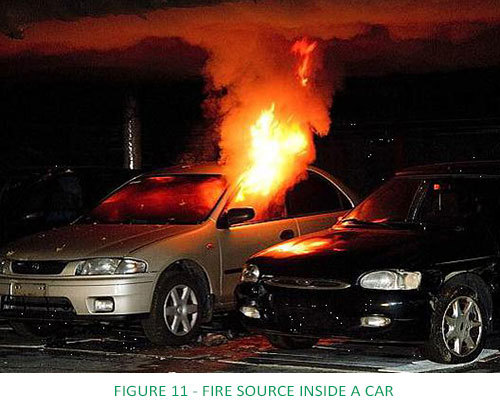

However, in most car fires, the fire source is either inside the car or in the engine compartment. Therefore, a sprinkler system is not effective as a means of extinguishing the fire, as the sprinkler cannot deliver water onto the seat of the fire, as the fire is covered protected by the actual bodywork of the car.

However, in most car fires, the fire source is either inside the car or in the engine compartment. Therefore, a sprinkler system is not effective as a means of extinguishing the fire, as the sprinkler cannot deliver water onto the seat of the fire, as the fire is covered protected by the actual bodywork of the car.

With a sprinkler system there is a real chance of combustion of flammable liquid - e.g. by rupture of the fuel tank - the so-called “pool fire”. Initially, the fuel is a liquid, and the application of a stream of water will splash it and spread the fire.

Another consideration is that the water will not cut off the oxygen supply as the fuel will not be "blanketed" by the water (fuel floats on water as it is less dense).

Because of the material composition of modern cars containing significantly more plastics, smoke production will prevail over temperature. With the fire source inside the car or under the hood, temperature radiation will be limited, but smoke production will increase dramatically.

In the case where the sprinkler detection is used to trigger the evacuation alarm, fire detection could be very late because of relative low smoke temperatures. In such a case there will be a lot of toxic smoke in the car park making evacuation and repression difficult.

Because of the dense smoke it is often not possible to find the exact fire location quickly. Confusion about the location of the fire can lead to a delay in the deployment of the fire brigade.

During the containment period, excessive amounts of steam can be produced which may last more than an hour. This will limit intervention by fire-fighters as the location of the fire is not visible.

International rules, such as NFPA, BS and the German GarVo require that smoke ventilation is required with sprinkler systems. However, the requirement is mostly for smoke clearance systems, which are not suitable for the objective 2 of smoke-free access for fire-fighters to a point close to the seat of the fire.

Combining sprinkler systems with a smoke control system may result in having the best from both worlds:

As such a sprinkler system may serve very well and complementary to a car park smoke ventilation system with jet fans. But it is of the essence that both systems are designed and installed in such a way that they do not have a negative effect on each other.

INFLUENCE OF JET FANS ON SPRINKLERS AND VICE-VERSA

A sprinkler is triggered by temperature. Smoke exhaust systems are (preferably) triggered by electronic smoke detection systems to ensure an early detection and start of the evacuation and smoke extract. Therefore, it is reasonable to assume that in case of a car fire in an enclosed car park, the reaction time of a smoke detection is much shorter than a sprinkler.

To ensure optimal function of both systems, the following has to be taken into account:

For the daily (CO) ventilation a jet fan system shall have a limited air velocity in the car park. Also in relation to fire safety this is very important:

Therefore, the thrust of jet fans in low speed should be limited to max. 20N (CO ventilation) and to max. 50N for the high speed (smoke ventilation).

Furthermore, the position of the jet fans in the car park should be coordinated with the parking spaces and smoke detectors. By placing the jet fans over the driving lanes and not over the parking spaces, the risk of having a jet fan in the direct vicinity of the car fire is minimized and therewith also the risk of influencing detection and sprinkler activation.

A big driving force for the movement of heat and smoke in case of a fire are the buoyancy forces due to the differences in air densities created by the temperature of the smoke. As long as the smoke temperature is higher than the adjacent ambient air, the smoke will remain buoyant and thus expand in all directions.

These buoyancy and entrainment forces generated by the fire will compete against the ventilation airflow and impulse force by the jet fan ventilation. For the jet stream to influence the sprinkler activation, the force of the jet stream should therefore be higher than the buoyancy force directly over the fire source.

CFD simulations show that even with a smoke control system with jet fans fully activated, the temperatures directly above the fire will be sufficient to activate the sprinkler within 5-10 min after start of the fire.

In figure 13 the temperatures are shown for a car fire after 10 min. Due to the buoyance forces of the hot smoke, the smoke also expands against the jet stream until the smoke is cooled down sufficiently to be controlled. Therefore, jet fan ventilation system will not interfere with the sprinkler activation above the fire source in case of a fire.

However, a delay in starting the jet fans of 5-7 min after detection would be advisable for two reasons:

In case the fire source is very close to a jet fan, the force implied by the jet fan on the smoke will be very limited due to the low air density, since:

Tj=Q x vo x ρ (3)

Where:

Tj : thrust of the jet fan [N]

Q : airflow of the jet fan [m³/s]

vo : outlet velocity of the jet fan [m/s]

ρ : density of the air / smoke [kg/m³]

Since density decreases at higher temperatures, the thrust of the jet fan also decreases where the buoyancy force of the smoke increases. Therefore, also the influence of the jet stream on sprinkler activation decreases.

Furthermore, if the temperature for sprinkler activation is not reached, there is no need for the sprinkler to be activated and consequential damage due to (polluted) water is prevented.

Figure 14 confirms that sprinklers would only be activated locally around the fire and therefore the effect of the sprinkler on the smoke ventilation system can be neglected.

Around the fire, smoke ‘washing’ can be expected, which will decrease the view on the seat of the fire. However because of lower smoke temperatures with sprinkler, a smoke control system with jet fan ventilation for smoke-free access for fire-fighters can be designed at lower critical air velocities and thus lower smoke extract rates, resulting in smaller smoke extract shafts and less jet fans.

As previously mentioned, NOVENCO has played a leading role in the development of car park ventilation systems.

The following provides a brief summary of the benefits to be achieved from using jet ventilation in car parking facilities:

SPACE SAVING

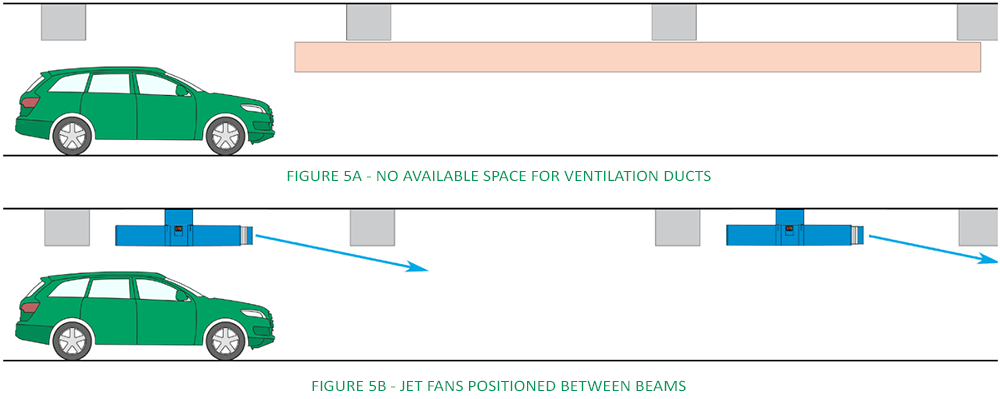

There is no need for space-consuming ducts in the car park, thus allowing the ceiling to be lower. This allows a better use of limited space in underground car parks and improves layout. Jet fans transport and distribute fresh air within a "giant duct" – the car park itself.

Various tests have shown that jet fans can be flexibly positioned. Individual fans can be positioned within a radius of 2m without affecting system efficiency.

When jet fan ventilation is used, directional "thrusts" of up to 45 m can be achieved. This allows complete air mixing and efficient CO dilution. Furthermore, it allows air to be directed into "dead" corners where there would otherwise be a high risk of CO accumulation.

With conventional ventilation systems where air is extracted through ducts, such pockets of high CO concentration may easily arise as suction cannot be directional.

With a conventional duct-based extraction system, a comprehensive network of ducts is required if all areas of the car park are to receive sufficient ventilation. Such ducts may cause problems for the design and layout of underground car parks. These problems can be avoided with Novenco jet fans.

Jet fans can be arranged in groups, controlled by corresponding groups of CO or CH4 sensors. The quantity of air to be moved can thus be regulated in response to requirements. As this is achieved at relatively low air velocities, energy is saved. Energy costs can typically be reduced to approx. 60% when jet fans are used.

In conventional systems, relatively high air velocities are used in order to reduce duct size, and this results in large pressure drops. When ventilation is required, the entire system is started, and energy unnecessarily wasted. This cannot be avoided as all ducts are interconnected.

There is no need to install ducts when jet fans are used in car parking facilities. In closed car parks there need only be a fresh air inlet and spent-air outlet. Pressure drop is thus limited to that occurring in damper, sound attenuator (if any) and shaft. This allows smaller motors and fans to be used, thus reducing sound levels.

There is no need to install ducts when jet fans are used in car parking facilities. In closed car parks there need only be a fresh air inlet and spent-air outlet. Pressure drop is thus limited to that occurring in damper, sound attenuator (if any) and shaft. This allows smaller motors and fans to be used, thus reducing sound levels.

On the other hand, jet fan ventilation systems require more cabling and larger electrical cabinets. However, even including these costs, jet fan ventilation systems are typically 30% cheaper to purchase and install than conventional systems.

Duct-based ventilation systems are often fitted with grilles that must be adjusted to achieve the required ventilation.

This is not necessary with jet fan ventilation systems as the fans are equipped with a directional grille that bends the air flow away from walls and ceilings. These grilles are factory-set and seldom require readjustment, although adjustment can easily be performed on site if necessary.

If there is no need for full ventilation, the quantity of air can be regulated by running the jet fans at half speed or by only operating a group of fans at a time.

Regarding the practical design of jet fan ventilation systems, determining the following five factors are of particular importance:

A) CO production

B) Ventilation quantity

C) Direction of air movement

D) Noise levels inside and outside the car park

E) Ventilation strategy in case of fire

Several factors affect the amount of CO produced. Modern cars produce less pollution than older models as a result of improved combustion and the use of catalytic converters. Cold engines produce more CO than hot engines. Also the driving speed affects CO production. All these factors must be taken into account when designing ventilation systems.

This also explains why CO production values differ from country to country. Some countries have relatively many old cars whilst in other countries, a greater proportion of the cars are new.

The ventilation rate for car park ventilation systems is normally provided in either international, national or even local standards and guidelines. For example, in the UK, a ventilation rate of 6 ACH (Air Changes per Hour) is required. In Portugal there is a requirement of 600 m³/h per parking space, and in Germany a ventilation rate of 6 m³/h per m² of car park is required for non-public car parks (for example a private parking or office building). For public car parks (for example a shopping centre) a ventilation rate of 12 m³/h per m² of car park is required.

The ventilation rate for car park ventilation systems is normally provided in either international, national or even local standards and guidelines. For example, in the UK, a ventilation rate of 6 ACH (Air Changes per Hour) is required. In Portugal there is a requirement of 600 m³/h per parking space, and in Germany a ventilation rate of 6 m³/h per m² of car park is required for non-public car parks (for example a private parking or office building). For public car parks (for example a shopping centre) a ventilation rate of 12 m³/h per m² of car park is required.

Another method is to calculate the required ventilation rate. For these calculations there are a number of available standards, such as for example the VDI 2053 from Germany, the NEN 2443 from The Netherlands or the SWKI 96-1 from Switzerland.

With these models the required ventilation rate can be calculated on the basis of (among others) the number of parking spaces, the distance travelled to reach them, the number of cold starts and hot starts within the car park and the number of cars arriving and leaving per hour.

To ensure optimal (transverse) ventilation, air supply and mechanical air exhaust should be positioned as far as possible from each other. Usually, the car park entrance/exit or access ramp is used as the fresh-air intake, while exhaust fans are positioned in the opposite corner.

It is important that requirements on noise levels within and outside the car park and the most expedient location for the exhaust system be considered early in the project planning phase.

Usually, it will be necessary to use sound attenuators, and space must be set aside for these and for a shaft.

The required ventilation rate for smoke ventilation strongly depends on the type of smoke ventilation system:

The objective of a smoke clearance system is to assist fire-fighters to clear smoke from a car park during and after a fire;

Here the objective is to provide clear smoke-free access for fire-fighters to a point close to the seat of the fire;

When dimensioning an underground car park, it is important to consider the location of air inlets and outlets. In most cases, it will be necessary to install an exhaust fan that can discharge the polluted air through a ventilation shaft.

Also unsuitable shaft locations must be taken into consideration. It may be possible to disguise the shaft so that it blends in with the surroundings, e.g. as an advertising pillar at a shopping centre.

When dimensioning the exhaust fan, the pressure drop through the entire system from the fresh air-intake to the discharge outlet must be taken into account. Usually, it is best to transport air through the discharge system by means of suction rather than pressure as this prevents spent air unintentionally spreading to other parts of the building.

Jet fans are used to distribute air within the car park and to ensure that "dead" areas do not occur.

In most car parks, clearance is limited to approx. 2.4-2.5 m. It is therefore important to ensure that fans are installed where there is no risk of collision. Alternatively, the clearance required by the consulting engineer must be taken into account when choosing fan size and/or location.

It is important to note whether the car park has visible girders as these may affect fan efficiency.

There must be a free distance to the nearest girder/wall of at least 0.5 m on the inlet side and 2.0 m on the outlet side. If girder height is greater than the installation height of the jet fan, it may be necessary to lower the fans.

Car parks have many noise sources – the most important being the cars themselves. On average, the sound pressure level inside the car park due to cars in motion is about 75 dB(A).

Furthermore, there may also be other technical installations inside the car park that contribute to the overall noise level.

Car park ventilation systems are is also a source of noise.

As a standard, car park jet fans are supplied with dual-speed motors. They are usually dimensioned to run at low speed most of the time and their noise emission will thus seldom be a problem.

Depending on type and size, the sound level from the car park jet fans varies between 45-61 dB(A) per fan during CO ventilation (low speed).

Therefore, these jet fans are insignificant noise sources in comparison with other sources within the car park.

In extreme situations, the fans can be switched to full speed. If the system includes an exhaust fan, the noise emitted by the fan must comply with applicable building regulations.

There may be differences in the permissible noise levels depending on location (industrial site or housing complex). Similarly, the time of day may affect the permissible noise level close to property boundaries or the windows of housing complexes.

In the '90s, NOVENCO pioneered the field of ductless car park ventilation systems with jet fans. Nowadays, these thrust ventilation systems are the new industry standard for the ventilation of enclosed car parks.

NOVENCO offers a wide range of car park jet fans, all with their own unique selling points (USP). All car park jet fans are compact and reliable units, with lifetime greased bearings and low power consumption. As a standard, the jet fans have 2-speed motors. At low speed, at least 80% of the operating conditions can be fulfilled at only 25 watts per 100 square meters of parking space.

For the extraction of contaminated air or the supply of fresh air, NOVENCO also offers a large range of efficient axial flow fans with airflows up to 110 m³/s (400.000 m³/h). This range of axial flow fans are also available as smoke fans tested and certified for temperatures up to 400 °C for 2hrs. Because no ventilation ducts are required inside the car park, these fans operate at low pressures and therefore require a minimal amount of energy. In combination with the special car park jet fans, energy savings up to 50% can be achieved in comparison with conventional car park ventilation systems with supply and extract ventilation ductwork.

Since 2020, NOVENCO also offers their highly efficient ZerAx® range of axial flow fans as certified variable speed smoke fan packages in accordance with the EN 12101 part 3 (2015). These smoke fan packages are high temperature tested and certified in combination with a frequency converter. In the event of a fire, this allows the use of variable speed-controlled smoke extract fans, without bypassing the frequency inverter. The outcome is a highly reliable solution with maximum flexibility to control smoke ventilation in case of a fire in combination with reduced operating costs for normal ventilation conditions.

For example, a comparison of the same system shows the differences between industry standard solutions such as the NOVENCO NovAx™ range of axial smoke fans and the high-efficiency range of ZerAx® smoke fans. With all selection variables set to the same setting, the electrical power input requirement for the NovAx™ ACN 1250 F300 is 65kW versus 56kW for the ZerAx® AZN 1250. The difference in power consumption is almost 14% which will lead to considerably lower running costs. Furthermore, power supply equipment, including UPS systems, can be dimensioned 14% smaller, resulting in lower initial investment costs. And with a considerably lower sound level, the ZerAx® is the obvious choice.

Please check the related products section below or contact us for more information on our design support, products and expertise for ventilation of your parking facility.

NOVENCO Building & Industry

Oeverup Erhvervsvej 50-52

4700 Naestved

Denmark

Tel. +45 70 77 88 99

info@novenco-building.com

DK 16 92 66 47

Opening hours OFFICE

Monday - Thursday 8.00 AM to 4.00 PM CET

Friday 8.00 AM to 3.30 PM CET

Opening hours GOODS IN and OUT

Monday - Thursday 6.30 AM to 2.30 PM CET

Friday 6.30 AM to 2.00 PM CET

NEED HELP?