NEED HELP?

WE ARE HERE TO HELP YOU

This area focuses on manufacturing-process industries for wood and food production.

Wood drying is the process of reducing moisture of the wood before its use. Wood needs to be dried in order to be used in construction or even as ordinary firewood, as the moisture content makes usage of wood difficult. Dried wood is lighter and therefore easier and more profitable for transportation. Electrical and thermal insulation properties of dried wood are highly improved. Drying process also increases the strength of the wood as well as is important to avoid decay of wood or any fungus growth.

In the food industry some processes require dehydration. Industrial food dehydration is often accomplished by freeze-drying, which means that food is flash frozen and put into a reduced-pressure system which causes the water to sublimate directly from the solid to the gaseous phase. In addition, another widely used industrial method of drying of food is convective hot air drying, which retain most of the nutritional properties of food if dried using appropriate drying conditions.

NOVENCO Building & Industry solutions for drying the wood reduce the moisture content and keep the wood from warping, cracking and becoming distorted. For the mechanical drying, where wood is dried under controlled temperature conditions and control humidity with a help of a ventilation system, forced circulation kilns are most common. In the drying kiln the air is circulated by means of fans, which may be installed outside the kiln chamber (external fan kiln) or inside it (internal fan kiln). Kiln drying is a process where heating conditions are controlled in kiln in order to dry the wood. Air circulation is important to carry heat and moisture away from the wood. Fans NOVENCO offers are durable and have the highest efficiencies available on the market. This means reliable ventilation system with low energy use and impact on the environment.

Our robust industry fans are suitable for operations in processes related to food industry. Whatever drying ventilation principle is employed, the NOVENCO solutions have low Total Cost of Ownership (TCO) due to low service requirements, low maintenance and low energy requirements. In addition to this come the long and renowned NOVENCO product lifetimes that underline the high payback on the capital cost as well as the high ROI.

The renowned NOVENCO NovAx™ axial fans are among the most efficient conventional axial fans on the market. The proven design is suitable for a variety of purposes such as exhaust of foul air and gases, as duct or supply fans or built into AHUs.

The NOVENCO ZerAx® axial fans are the next step in fan design and are unprecedented with ground-breaking fan efficiencies of up to 92%. The design sets new standards for fan design as it lowers the power consumption and noise levels significantly. The ZerAx axial fans are the most energy-efficient on the market today and have lifetimes of 20+ years, which contribute to sustainability and guarantee low maintenance costs.

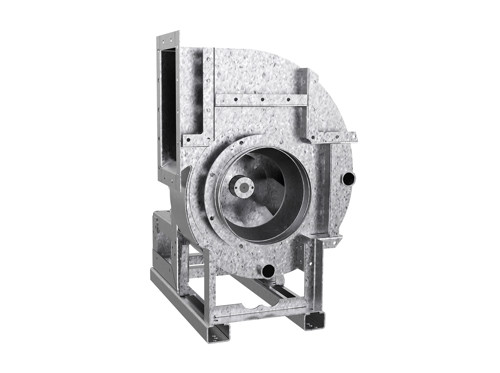

The NOVENCO centrifugal fans are as renowned and durable as the NovAx and ZerAx fans. They built on NOVENCO’s many years of experience with fan design and are sturdy examples of what to expect of these robust and compact fans.

NOVENCO Building & Industry

Oeverup Erhvervsvej 50-52

4700 Naestved

Denmark

Tel. +45 70 77 88 99

info@novenco-building.com

DK 16 92 66 47

Opening hours OFFICE

Monday - Thursday 8.00 AM to 4.00 PM CET

Friday 8.00 AM to 3.30 PM CET

Opening hours GOODS IN and OUT

Monday - Thursday 6.30 AM to 2.30 PM CET

Friday 6.30 AM to 2.00 PM CET

NEED HELP?