NEED HELP?

WE ARE HERE TO HELP YOU

NOVENCO Building & Industry has supplied jet fans for longitudinal ventilation of road and rail tunnels since the early 1970s. Today, the company ranks among the world’s leading manufacturers of tunnel ventilation and smoke control systems.

In special cases ventilation may be required to control the temperature inside the tunnel.

In normal tunnel operation, exhaust gases are released in the tunnel by traffic. Next to the exhaust gases also the wear of the tyres and the road surface causes the formation of dust particles. Within the tunnel this leads to certain concentrations of gases and particles, which can be dangerous to the health and safety situation in the tunnel. Higher particle concentrations will also lead to lower visibility.

For shorter, uni-directional tunnels, the natural ventilation in combination with the traffic drag effect can already be sufficient. In case of longer tunnels, mechanical ventilation may be necessary.

By using ventilation, the concentration of dangerous gases and particles can be controlled to meet the requirements for safe tunnels. In the calculation of the required ventilation, the background concentration of gases and particles also has to be taken into account.

* Based on 60 km/h, uphill gradient of +6 ° vs. downhill gradient of -6 °.

In case of fire, persons staying or trapped in tunnels are at risk. The threats evolve quickly in the form of hot gases, heat radiation, reduced visibility and toxic gases. Most victims in fires die or suffer because of long exposures to hot and toxic gases as well as due to loss of visibility which hide escape routes. In the first phases of a fire, the road users are threatened, in later phases particularly the emergency workers.

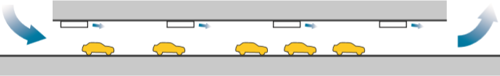

With longitudinal ventilation, fresh air enters via the tunnel entrance portal and is exhausted at the tunnel exit portal. The airflow through the tunnel can be generated and controlled with jet fans. The thrust of the jet fans is applied to the air as impulses, causing the air to move forward.

Principle of longitudinal ventilation

With longitudinal ventilation, the pollution concentration increases in the direction of the ventilation, since no fresh air is supplied or extracted inside the tunnel. The level of pollution can be detected with special gas detection and visibility measurement systems. Based on the information from these detection systems, the necessary ventilation can be effectively regulated by turning the jet fans on or off.

The maximum tunnel length that can be ventilated by longitudinal ventilation is limited by the maximum allowable pollution and visibility in the tunnel tube. Depending on the amount and type of vehicles, the maximum tunnel length that it is possible to ventilate with longitudinal ventilation is 3 - 6 km.

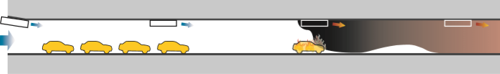

In case of a fire, the direction of the smoke and gases can be controlled effectively, even in case of very large fires. The tunnel part upstream from the fire can be kept completely smoke free, which protects persons in that part of the tunnel from smoke and toxic gases. Upstream, the fire brigade and other emergency services also have good access.

Principle of smoke control

Downstream the tunnel is completely filled with smoke. With uni-directional traffic this is no problem, since the vehicles downstream leave the tunnel as part of normal traffic flow.

The tunnel jet fans downstream of the fire are exposed to higher (smoke) temperatures. Therefore, these jet fans must be able to operate for a short period at elevated temperatures. NOVENCO tunnel jet fans have been tested and certified at an independent test and certification institute in Germany for temperatures up to 400°C for 2hrs.

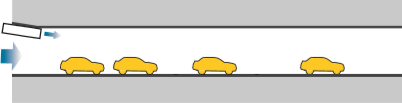

To prevent the failure of jet fans in case of a fire, jet fans are often placed close to the tunnel entrance. These type of jet fans are often referred to as injection jet fans or open injectors. By placing the jet fans in a small angle with the tunnel axis, the installation efficiency can be improved.

Longitudinal ventilation with jet fans, position of injector fans

Static and dynamic factors influencing on thrust

* In case of unidirectional traffic, the piston effect of the moving traffic causes a positive drag effect. If the piston effect of the traffic is large enough, the jet fans can be switched off.

The effective thrust of a jet fan placed in a corner is much lower than a jet fan installed in the middle of the tunnel with sufficient distances to the ceiling and walls. This so-called installation factor of jet fans can be greatly improved by using air deflectors on the outlets of the jet fans. The type and design of air deflectors has proven to be a big influence on the performance and installation efficiency of the jet fans. NOVENCO uses specially designed aerodynamic wing-shaped air deflectors with a very high efficiency and low sound generation.

For the calculation of tunnel ventilation systems, NOVENCO uses both deterministic and probabilistic calculation models. To check the design, NOVENCO has a specialised department for CFD (Computational Fluid Dynamics) calculations and simulations. Our tunnel specialists also have experience with IDA Tunnel, a comprehensive road and rail tunnel ventilation and fire simulation software, used by leading tunnel design companies worldwide. The computed results can be animated in full 3D representations of the tunnel.

In deterministic calculation models, all input is set to fixed values on the basis of which the tunnel ventilation system is designed. By changing input data such as wind conditions, traffic composition, tunnel construction data, fire size and location and tunnel jet fan selections and position in the tunnel, a static calculation is made.

With the computational power we have nowadays, we can also use probabilistic calculation models. These models use a stochastic process, in which the variables are set using a probability distribution with a minimum and maximum value. With all possible combinations and variations of these input variables, deterministic calculations are made and based on the probability of the input variables and acceptable failure probabilities.

For example, the probability of a 20 MW fire is greater than the probability of a 100 MW fire. In this context, the acceptable failure rate for a 20 MW fire is much lower than for a larger fire. The same applies to the wind effect on the portal. Where a wind speed of approximately 3 to 5 m/s (wind force 3) is quite normal, the chance of a wind speed of more than 10 m/s is rather exceptional. This is why the probability of failure is also adjusted accordingly. A risk analysis can then be carried out on the basis of these stochastic loads, in which the design of the ventilation system is assessed.

This probabilistic calculation model is described in detail in the “Recommendations ventilation for road tunnels”, published by Rijkswaterstaat (Dutch Road Authorities).

Since the early '70s, NOVENCO has supplied jet fans for road, rail and metro tunnels.

Particularly in the Netherlands, many tunnels under major rivers have been built using the immersed-tunnel method, beginning with the Maastunnel in the centre of Rotterdam, about fifty years ago. With this method, the (rectangular) tunnel elements are immersed and connected. To prevent high construction costs, the elements are built with a minimum height, taking into consideration the traffic height and an absolute minimum height for the technical installations.

In those cases where installation height is limited, NOVENCO Building & Industry has a special tunnel fan range with space-saving jet fans. By using a rectangular outside shape in combination with a special fan construction, these jet fans use up to 20% less installation height in the tunnel, whilst maintaining the thrust and thrust efficiency. Due to the shape of the silencers, more silencing material can be applied, resulting in a lower sound level compared to the same tunnel jet fan in a round execution.

Next to the tunnel jet fans, NOVENCO also offers a large range of highly efficient axial flow fans up to 2 meters in diameter with airflows up to 110 m³/s (400.000 m³/h). Our axial flow fans are also available as smoke fans tested and certified for temperatures up to 400 °C for 2hrs.

Since 2020, NOVENCO also offers their highly efficient ZerAx® range of axial flow fans as certified variable speed smoke fan packages in accordance with the EN 12101 part 3 (2015). These high temperature tested and certified packages with a smoke fan and frequency converter, allow the use of variable speed-controlled fans in the event of fires, without bypassing the frequency inverter. The outcome is maximum reliability and flexibility to control smoke ventilation in case of a fire in combination with reduced operating costs for normal ventilation conditions.

For example, a comparison of the same system shows the differences between industry standard solutions such as the NOVENCO NovAx™ range of axial smoke fans and the high-efficiency range of ZerAx® smoke fans. With all selection variables set to the same setting, the electrical power input requirement for the NovAx™ ACN 1250 F300 is 65kW versus 56kW for the ZerAx® AZN 1250. The difference in power consumption is almost 14% which will lead to considerably lower running costs. Furthermore, power supply equipment, including UPS systems, can be dimensioned 14% smaller, resulting in lower initial investment costs. And with a considerably lower sound level, the ZerAx® is the obvious choice.

Please check the related products section below or contact us for more information on our products and expertise for your road, rail and metro tunnel projects.

NOVENCO Building & Industry

Oeverup Erhvervsvej 50-52

4700 Naestved

Denmark

Tel. +45 70 77 88 99

[email protected]

DK 16 92 66 47

Opening hours OFFICE

Monday - Thursday 8.00 AM to 4.00 PM CET

Friday 8.00 AM to 3.30 PM CET

Opening hours GOODS IN and OUT

Monday - Thursday 6.30 AM to 2.30 PM CET

Friday 6.30 AM to 2.00 PM CET

NEED HELP?